Technical Information on Intek Heat and Chemical Resistant RTV Silicone Sealants

All of our RTV silicone sealants and adhesives have very good resistance to chemicals, high temperature, acid, alkaline and most industrial fluids. Intermittent exposure to fuels is fine but not resistant for continuous contact.

Common Chemical examples are Formaldehyde, Chlorine, Oil, Bio Diesel, Hydrogen Peroxide, Caustic and Industrial Solvents.

| RTV 382 | AG 300 | XTS 320 | Flowsil | |

|---|---|---|---|---|

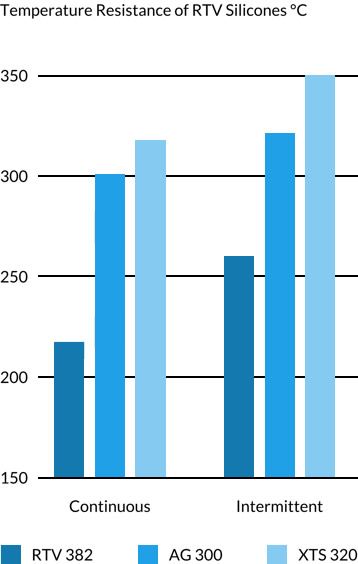

| Operating Temperature | -55℃ +260℃ | -55℃ +300℃ | -55℃ +320℃ | -55℃ +200℃ |

| Viscosity | Non Slump Paste | Non Slump Paste | Non Slump Paste | Self Leveling Liquid |

| Tensile Strength MPa | 1.9 | 2.9 | 1.9 | 1.2 |

| Cure Time | 3 mm per 24 hours | 3 mm per 8 hours | 3 mm per 24 hours | 3 mm per 24 hours |

| Colour | Translucent Clear | Metallic Silver | Orange / Brown | Translucent Clear |

| Chemical Resistance | Good | Recommended | Excellent | Fair |

| Temperature | Good | Excellent | Recommened | Good |

| Weathering UV Resistance | Good | Recommended | Excellent | Fair |

| Electrical Properties | Recommended | Good | Excellent | Recommended |

| Adhesive Strength | Good | Recommended | Excellent | Limited |

ADHESION PERFORMANCE

| AG 300 | RTV 382 | XTS 320 | |

|---|---|---|---|

| Aluminium / Steel | Excellent | Excellent | Excellent |

| Stainless Steel | Excellent | Good | Good |

| Copper | Good | Excellent | Excellent |

| Glass Filled Nylon | Excellent | Good | Excellent |

| Polypropylene / PE | Not Recommended | Not Recommended | Not Recommended |

| Rigid PVC | Good | Good | Excellent |

| Silicone Rubber | Excellent | Excellent | Excellent |

| Chloroprene | Good | Fair | Good |

| Glass | Excellent | Excellent | Excellent |

| Concrete | - | - | - |

| Ceramic | Good | Good | Excellent |

| Carbon Fibre | Good | Good | Excellent |

| Powder Coatings | Excellent | Excellent | Excellent |

| Woods | Excellent | Good | Good |

How much will I get from a 310 ml cartridge?

6 mm x 3 mm bead = 18 Metres approx

6 mm x 6 mm bead = 9 Metres approx

Will heating RTV’s accelerate the cure time?

No,as it will eliminate the required moisture. Note – If speed of cure is important see – AG 300 – Fast curing one part sealant (6-8 hours) RTV 2 – Two hour curing 2 part sealant.

How do I prepare my surface?

Clean and de-grease metals using an industrial solvent like our Metal Cleaner or IPA. Avoid detergents as they can leave a residue Light abrasion will also be helpful prior to cleaning.

Can silicone sealants be over painted?

Sorry no – but our polyurethane’s can.

Are silicones flame retardant?

Yes our silicones will not burn unless a direct flame is applied. Some grades meet UL 94 requirements. If they do burn minimal fumes are given off so toxicity is not a concern.